Predictive Maintenance in Railway Systems: Elevating RAMS Performance with Data-Driven Strategies

Introduction

In an industry where safety, reliability, and efficiency are paramount, predictive maintenance (PdM) has emerged as a transformative approach to asset management in railway systems. By anticipating failures before they occur, railway operators can enhance Reliability, Availability, Maintainability, and Safety (RAMS) while significantly reducing lifecycle costs. This blog explores the principles, technologies, and strategic benefits of predictive maintenance within the context of railway operations.

What is Predictive Maintenance?

Predictive maintenance involves the real-time monitoring of asset conditions using data-driven tools to forecast when maintenance should be performed. Unlike reactive (post-failure) or preventive (scheduled) maintenance, PdM aims to optimize asset availability by servicing components only when necessary—just before a potential failure.

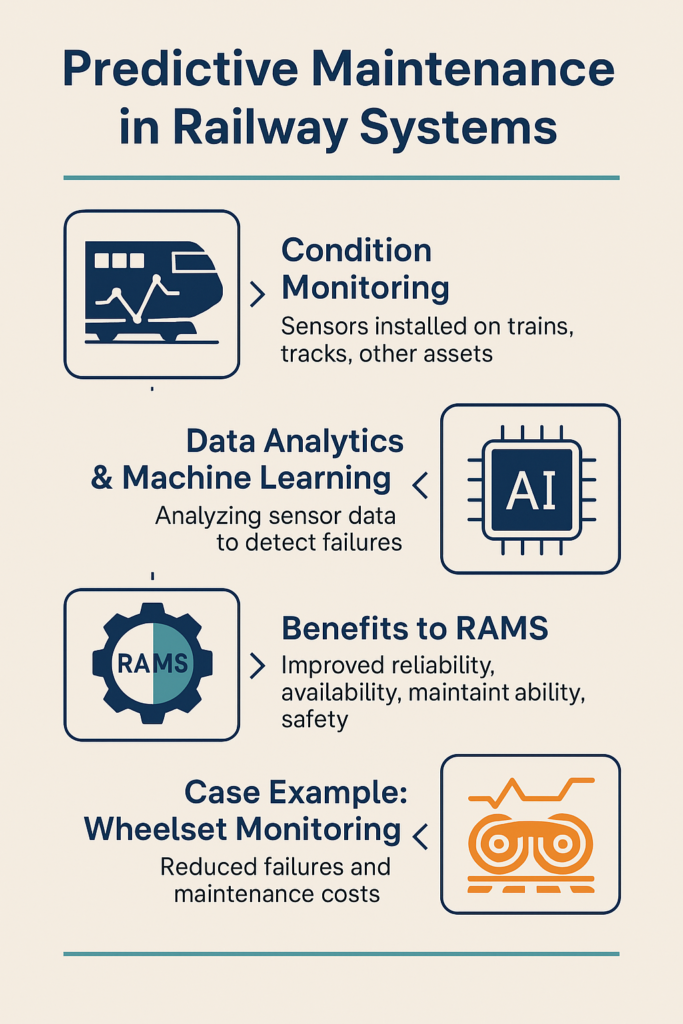

Key Concepts:

- Condition Monitoring: Using sensors to track parameters such as vibration, temperature, and pressure.

- Data Analytics & Machine Learning: Predictive models analyze trends and identify anomalies.

- Remaining Useful Life (RUL): Estimating the time left before asset failure.

Enabling Technologies in Railway Systems

Modern railways benefit from a suite of technologies that facilitate predictive maintenance:

1. Internet of Things (IoT) and Smart Sensors

Sensors installed on trains, tracks, and critical systems collect high-frequency data on asset health.

2. Edge Computing

Preliminary data processing at the source minimizes latency and bandwidth usage.

3. Cloud Analytics and AI

Centralized platforms perform deep analytics and train predictive algorithms to detect early signs of wear or malfunction.

4. Digital Twins

A virtual replica of physical assets allows operators to simulate scenarios and predict future behavior.

Application Areas in Rail

Predictive maintenance can be deployed across various rail subsystems:

- Rolling Stock: Monitoring wheel wear, brake pads, traction motors, and HVAC systems.

- Track Infrastructure: Identifying track deformation, ballast issues, and turnout condition.

- Signaling & Control: Ensuring performance of relays, point machines, and interlockings.

- Energy Systems: Monitoring substations and overhead line equipment for voltage irregularities.

Benefits to RAMS and Operational Efficiency

The integration of predictive maintenance directly contributes to improving the four RAMS pillars:

| RAMS Element | PdM Impact |

|---|---|

| Reliability | Reduced unscheduled downtime via early fault detection. |

| Availability | Increased system uptime due to better scheduling and reduced repair times. |

| Maintainability | Maintenance is performed only when needed, based on condition, streamlining resources. |

| Safety | Avoids catastrophic failures, especially in safety-critical subsystems like braking or signaling. |

Case Example: Wheelset Monitoring on High-Speed Trains

A European rail operator implemented a PdM program for wheelsets using vibration sensors and AI. Over 18 months:

- Unscheduled failures dropped by 40%.

- Maintenance costs reduced by 18%.

- RAMS targets exceeded across all KPIs.

Challenges and Considerations

Despite the benefits, deploying PdM requires overcoming certain hurdles:

- Data Quality: Inaccurate or missing data can impair model performance.

- Initial Investment: High cost of sensors and IT infrastructure.

- Workforce Adaptation: Requires training maintenance personnel in data interpretation and new workflows.

- System Integration: Aligning PdM tools with legacy maintenance management systems.

The Future of Predictive Maintenance in Rail

Looking ahead, predictive maintenance will become a standard component of digital rail asset management, particularly as more operators embrace ERTMS/ETCS and other digitalization initiatives. Integration with System Assurance and Asset Lifecycle Management will further amplify its impact on RAMS compliance.

Conclusion

Predictive maintenance is not just a buzzword—it’s a strategic enabler for safe, efficient, and cost-effective railway operations. By leveraging advanced monitoring and analytics, railway stakeholders can achieve greater asset control, minimize disruptions, and ensure that their systems meet the highest safety and performance standards.

To learn more about railway safety and engineering, explore our RAMS training courses at https://ramsrail.com/rams-courses/.